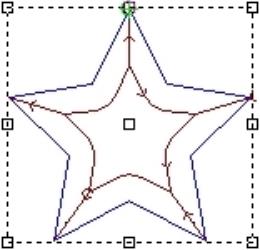

Engrave Toolpaths

![]()

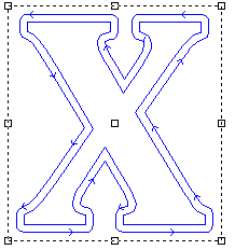

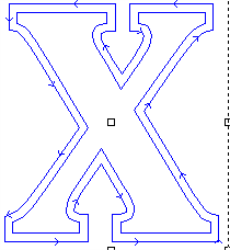

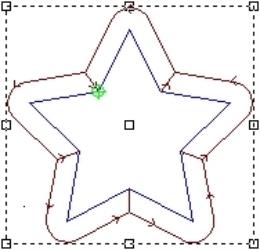

Create 2D or 3D engraving toolpaths. 2D toolpaths follow the selected contour exactly to add a beveled effect. 3D toolpaths use the shape of the engraving tool to more accurately cut out sharp corners.

Cut Parameters

Parameter for Depths, Passes, Feed and Speeds, and Direction match the other toolpath Cut Parameters.

| 3D Engrave Toolpath |

When checked, the engrave will be created as a 3D toolpath. If unchecked, a 2D toolpath will be generated. |

| External or Internal |

When 3D Engrave Toolpath is checked, it must be specified if the toolpath should pass to the inside or outside of the contour.

3D engrave toolpaths require all selected objects to be combined into a single toolpath group. Existing toolpath groups included in the selection will be deleted when creating engrave toolpaths.

|

Strategy Parameters

The first tool defined in the engrave strategy is always the engrave tool, and the second tool is defined as the rough tool. Toolpaths for the rough tool are only generated if required by the engrave cut.

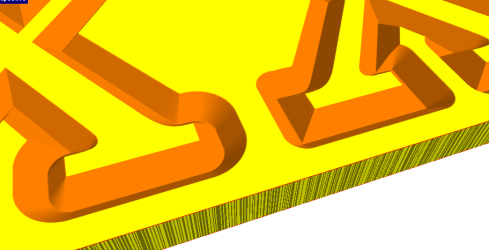

Square Corners

For External 3D Engrave toolpaths, there is an additional option for square corners which will create squared toolpaths at corners in the contour and change the finished surface.